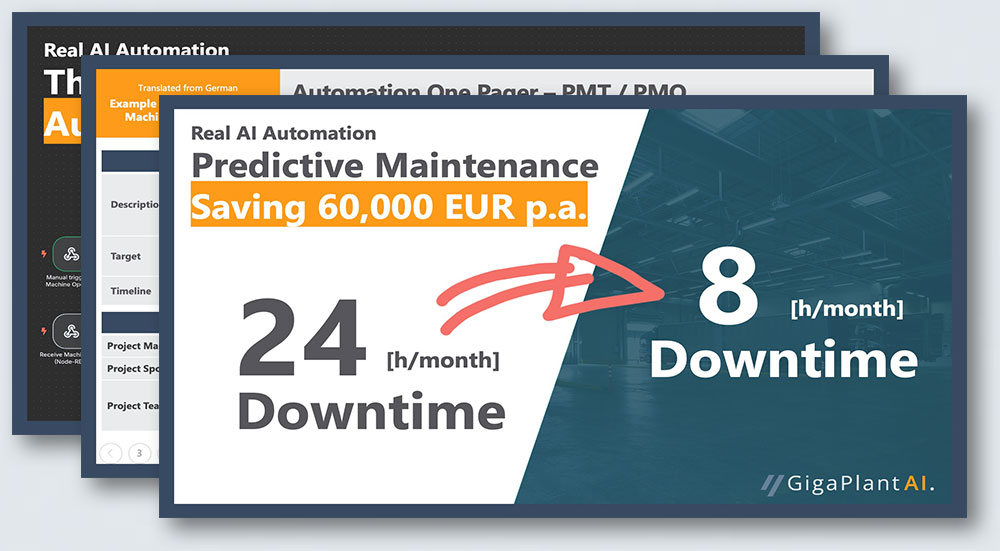

Shift Breakdown Times with AI Automation.

Learnings from a tier-1 automotive supplier that achieves stunning 46% decrease of downtimes with AI Automation.

Download: Real AI Automation Insights (PDF)

Get 5 real examples free to copy & paste for your industrial needs.

*we sent you the PDF right to your inbox

In today’s hyper-competitive manufacturing environment, downtime is more than just a nuisance — it’s a silent profit killer. For Tier-1 suppliers in the automotive industry, where just-in-time delivery and production precision are non-negotiable, every minute of unplanned stoppage carries significant cost.

In this post, we’ll take a closer look at how one Tier-1 automotive supplier achieved a 46% reduction in downtime by implementing AI-powered automation workflows — and what your factory can learn from it.

The Problem: Hidden Inefficiencies Behind the Machines

Despite years of continuous improvement and lean practices, the supplier struggled with recurring unplanned equipment downtime, particularly in their welding and stamping lines. Traditional root cause analysis was slow, maintenance was reactive, and communication between MES (Manufacturing Execution Systems) and operators was fragmented.

- Mean Time Between Failures (MTBF) was decreasing.

- Preventive maintenance schedules were either too frequent or too late.

- Technicians often received unclear or delayed alerts.

- Management lacked real-time visibility on downtime patterns.

The result: rising costs, bottlenecks in production, and delivery risks for key OEM contracts.

Download: Real AI Automation Insights (PDF)

Download: Real AI Automation Insights (PDF)

Get 5 real examples free to copy & paste for your industrial needs.

*we sent you the PDF right to your inbox

*we send you the 5 real examples free to copy & paste for your industrial needs

The Solution: AI Automation Meets Smart Factory Operations

The turning point came when the supplier partnered with GigaPlantAI to implement an AI Automation Layer on top of their existing systems — using tools like n8n, Make.com, and custom AI agents.

Here’s what was deployed:

1. Downtime Detection Bots

AI agents monitored machine signals and SCADA data to detect anomalies. Instead of relying solely on PLC error codes, machine learning models were trained to recognize early signs of failure patterns.

2. Smart Maintenance Triggers

When risk thresholds were exceeded, the system automatically generated a service ticket in the CMMS (Computerized Maintenance Management System), assigned the right technician, and sent alerts via Microsoft Teams and SMS.

3. Root Cause Suggestion Engine

An AI copilot aggregated historical failure logs, environmental data, and operator notes to suggest likely root causes and first-response actions — drastically reducing troubleshooting time.

4. Integrated Downtime Dashboards

Real-time dashboards pulled data from MES, IoT sensors, and maintenance logs to give supervisors a live view of machine health and downtime trends — enabling proactive decisions.

The Impact: A 46% Downtime Reduction in 3 Months

After deploying these AI automation workflows across two production lines, the results were dramatic:

- Downtime reduced by 46% compared to the previous quarter.

- Troubleshooting time cut by 62%.

- Maintenance response times improved by 41%.

- OEE (Overall Equipment Effectiveness) increased by 9.7 percentage points.

“What used to take 2 hours now takes 20 minutes — and we no longer have to guess. AI tells us what to check, and when.” — Maintenance Lead, Tier-1 Supplier

What This Means for Your Factory

This case proves that AI Automation isn't just a buzzword — it's a practical, scalable solution to real manufacturing problems.

By combining intelligent monitoring, automated workflows, and AI-driven insights, even complex, high-volume operations like Tier-1 suppliers can see immediate gains in efficiency, cost savings, and operational resilience.

And the best part? These systems didn’t require ripping out existing infrastructure. They were layered on top of current ERP, MES, and SCADA setups — minimizing disruption and maximizing ROI.

Ready to Transform Your Downtime into Uptime?

At GigaPlantAI, we specialize in helping factories unlock the hidden power of automation using AI-driven, no-code solutions. Whether you're in automotive, aerospace, or industrial equipment — the opportunity is massive.

Download: 5 AI Templates from Automotive Manufacturers

Get 5 real examples free to copy & paste for your industrial needs.

*we sent you the PDF right to your inbox