Use Cases.

Discover how leading factories reduce downtime, cut energy costs, and speed up quality checks using AI & automation.

Download: Real AI Automation Insights (PDF)

Get 5 real examples free to copy & paste for your industrial needs.

*we sent you the PDF right to your inbox

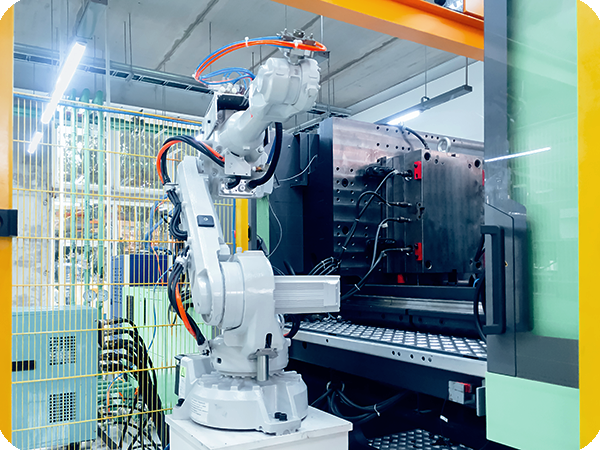

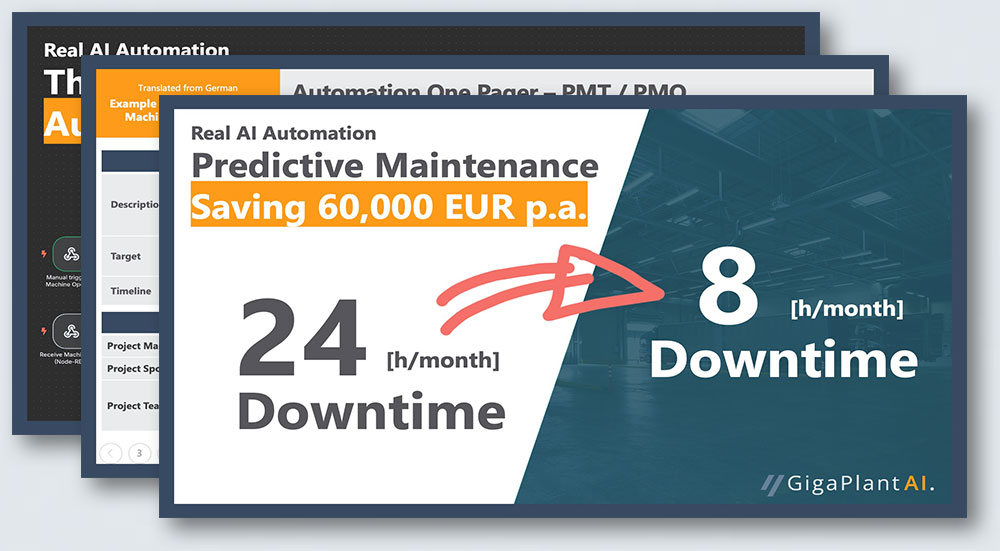

Use Case 1: AI Prevents Failures and Cuts Downtime by 42%

A leading Tier 1 automotive supplier struggled with frequent breakdowns on injection molding lines. Unplanned downtime caused missed deliveries and rising maintenance costs.

They launched a pilot using AI-powered predictive maintenance, combining sensor data and automated workflows with support by our AI Toolbox. The system detects anomalies like temperature spikes or cycle time deviations and automatically alerts the maintenance team.

Within weeks, the company saw fewer breakdowns, faster interventions, and major cost savings.

Key Results & Savings

Prevent breakdowns before they happen with our AI workflows

Download: Real AI Automation Insights (PDF)

Download: Real AI Automation Insights (PDF)

Get 5 real examples free to copy & paste for your industrial needs.

*we sent you the PDF right to your inbox

*we send you the 5 real examples free to copy & paste for your industrial needs

Use Case 2: AI Cuts Inbound Inspection Time by 80%

At a machinery manufacturer, incoming inspections were slow and manual. Staff checked parts by hand and filed paper reports, delaying production.

To streamline the process, the company implemented an AI-based image recognition system combined with automated workflows.

Replace slow manual checks with instant AI-powered part inspection

With AI-based image recognition and workflows designed with support by GigaPlant AI, parts are now photographed, classified, and compared to specs automatically. Issues trigger instant reports and supplier notifications.

Key Results & Savings

Use Case 3: AI Energy Analysis Cuts Factory Costs by €95K/Year

A large manufacturing plant faced rising energy bills, especially during peak production hours. The site ran 24/7, but energy data was only reviewed monthly — too late to act on real-time waste.

They introduced AI-based energy monitoring with live data feeds, built dashboards with use of the GigaPlant AI, and used automated alerts to highlight spikes and inefficiencies. The system detects unusual patterns, idle equipment, and compares actual usage to optimal benchmarks.

As a result, machines now run more efficiently, night-shift consumption dropped, and facility teams react to issues in real time.

Key Results & Savings

Cut energy waste in real time with AI-driven usage insights

Download: 5 AI Templates from Automotive Manufacturers

Get 5 real examples free to copy & paste for your industrial needs.

*we sent you the PDF right to your inbox